Sansi LED: Sustainable LED Lighting and Integrated LED Display

Delivering premium and professional LED Display, LED Lighting, Smart City Integration solutions, trusted by over 60,000 companies worldwide everyday. From industrial lighting to commercial lighting, from outdoor advertising to XR & VR production, Sansi LED greatly improves the quality and sustainability of your business with 30 years of expert experiences.

Heat dissipation technology plays a crucial role in various fields of modern industrial production and technology. Effective heat dissipation design can ensure the long-term stable operation of equipment, improve efficiency and service life. This blog aims to introduce the 5 most efficient and commonly used heat dissipation materials favored in the production process.

Aluminum is a common heat dissipation material with good thermal conductivity and cost-effectiveness. Aluminum heat sinks are widely used in electronic products such as computers and mobile phones. Its advantages include lightweight and good heat dissipation performance, but its corrosion resistance is slightly inferior to other materials.

Copper is another commonly used heat dissipation material with excellent thermal conductivity and corrosion resistance. Copper heat sinks are usually used for heat dissipation in high-power devices such as servers and industrial control equipment. Its drawback is the heavier weight and relatively higher cost.

Aluminum alloy heat sinks combine the advantages of aluminum and other metals, with good thermal conductivity and strength. They are widely used in automotive, aerospace, and other fields. Aluminum alloy heat sinks are not only lightweight and durable but also moderately priced.

Plastic heat sinks are lightweight and convenient, suitable for occasions with low heat dissipation requirements. They are commonly found in household appliances and other products, with low price and easy processing.

Ceramic, as a special material, has excellent insulation and high-temperature resistance, suitable for heat dissipation requirements in various extreme environments. Ceramic heat sinks are not easily deformed and can effectively separate heat sources from other components, ensuring stable operation of equipment.

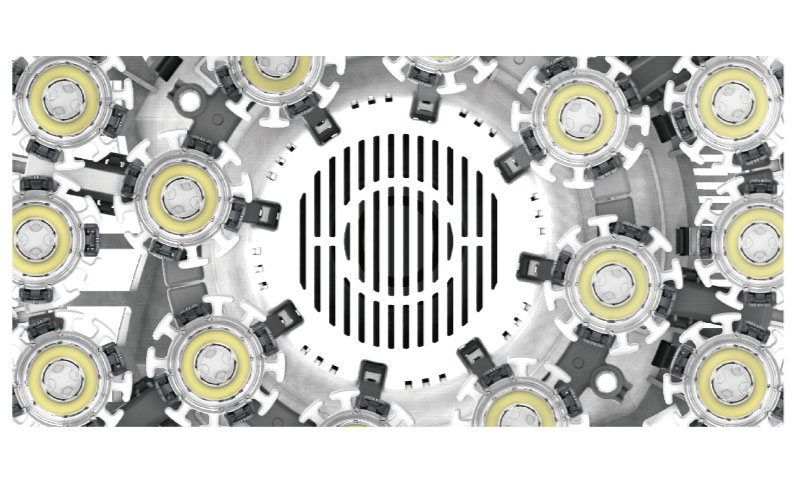

Compared to traditional metal heat sinks, ceramic-based heat sinks can better dissipate heat, improve heat dissipation efficiency, and ensure long-lasting stable lighting of LED lighting products. At the same time, ceramic heat sinks are not affected by corrosion, more durable and reliable, effectively extending the service life of products.

Sansi LED lighting products have always made full use of the excellent characteristics of ceramic, using it as heat dissipation material to enhance the heat dissipation performance and durability of the products. From street lights operating tirelessly in countless transportation hubs to light bulbs used daily in every household, Sansi LED has developed the most outstanding and reliable LED lighting solutions for various lighting scenarios.

-

NO DATA