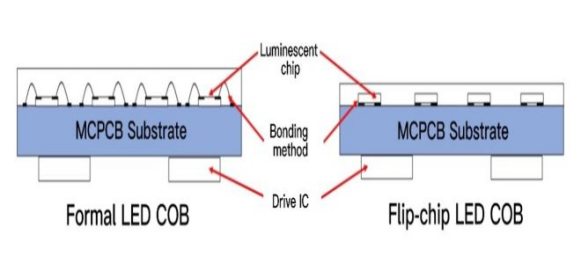

As a mainstream display technology in the industry, the reliability of fine-pitch LEDs has long been verified in multiple key areas. With the increasing pursuit of demanding LED display quality by customers, Flip Chip COB packaging structure, as an iterative technology of fine-pitch LEDs, can meet higher display density requirements. The challenging technology of the flip chip structure is improved compared to traditional methods due to its smaller size, simplifying the production process while providing better display effects (brighter brightness and higher contrast), coupled with good heat dissipation without gold wires, making it highly sought after in the market.

At the same time, its high light efficiency, compact size, and lower thermal resistance make it suitable for high-power LED packaging units. Its production process is more reliable and can be viewed as an upgraded product of conventional chip packaging, with a technical direction leaning toward smaller sizes and higher power unit packaging for LED chips. There is also a saying that "the smaller the pixel pitch, the more obvious the advantages of flip chip."

Aside from cost considerations, the structural advantages of flip chip COB packaging bring the following direct benefits to the display market:

Broad Application Prospects: Its application range is extensive, catering to the needs of the information visualization era, capable of addressing both large-area displays and high-end applications with micro-pitch small sizes. This includes command centers, security monitoring, broadcast studios, high-end showrooms, and even home theaters.

Seamless Splicing with Ultra HD Resolution: It offers excellent surface uniformity, allowing for seamless splicing between modules. 2K, 4K, and 8K display resolutions can be freely combined, making it the mainstream choice for future ultra-high-definition large screen display walls.

Chip-Level Micro Pitch: The physical space size of flip chip COB structure is only limited by the size of the light-emitting chip, breaking the pixel pitch limits of traditional packaging. The pixel pitch can be reduced to 0.X mm, with a corresponding product available for every 0.1 mm. Compared to traditional products, under the same brightness steady-state conditions, the wireless packaging offers better heat dissipation, lower surface temperatures of the screen, and a more comfortable viewing experience at close distances.

As high-quality solutions for flip chip COB light sources gradually become well-known, it may become a significant mainstream product in the market.