The Indispensable Role of Industrial Lighting

No matter what kind of business you are in, industrial lighting is crucial for both work efficiency and safety. Imagine if your employees had to work under poor lighting conditions, would they be able to maintain a good mood and high productivity? This is especially important in high-risk work environments like warehouses, construction sites, and mining fields, where proper lighting ensures workers can clearly see their surroundings, stay focused, reduce accident risks, and boost productivity.

Successful businesses often prioritize their employees’ work environment and carefully select their lighting equipment. Given the large size of most industrial facilities and the difficulty of frequent maintenance, LED lights have become the top choice for industrial lighting.

Why is Thermal Management Critical in LED Lights?

When choosing LED lights, we typically expect them to have high durability, excellent light efficiency, low maintenance costs, and a long lifespan. To meet these expectations, it’s crucial to consider thermal management, particularly in high-power LED applications such as industrial lights.

Firstly, it’s important to understand that LEDs emit light by converting electrical energy into light. However, during this process some electricity is converted into heat, causing the LEDs to warm up. The heat capacity of the LED chip is quite small, and accumulated heat will quickly raise the junction temperature of the chip. Operating at high temperatures for extended periods can significantly shorten the LED chip’s lifespan. Moreover, excessive junction temperature can accelerate the decline in LED efficiency, negatively impacting the color temperature and brightness of the light.

Therefore, effective heat dissipation is essential for a satisfying LED light product. In this context, both MCPCB and ceramic heat dissipation technologies, which are used to enhance the heat dissipation of LED chips, play important yet distinct roles.

What is MCPCB Technology?

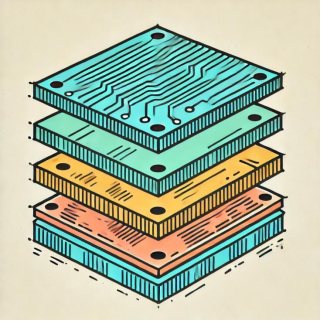

MCPCB, or Metal Core Printed Circuit Board, enhances heat dissipation by attaching a printed circuit board to a metal substrate. MCPCB typically uses aluminum or copper as its base material, combined with an insulating layer and copper foil to form a unique structure. Compared to early FR4 circuit boards, MCPCB offers improved heat conductivity and is cost-effective, making it a popular choice for low- and medium-power LED products.

Limitations of MCPCB

MCPCB has its limitations when it comes to heat management. While aluminum and copper have excellent heat conduction properties, the polymer insulation layer in MCPCB has a thermal conductivity of only 0.2 to 0.5 W/mK, which greatly reduces overall heat dissipation efficiency. Even with the addition of high-conductivity materials, the overall thermal conductivity of MCPCB is still limited to around 3 to 5 W/mK. Furthermore, during the manufacturing process, metal deformation caused by stamping can lead to issues with insulation stability, ultimately compromising the long-term performance of the LED.

What is Ceramic Heat Dissipation Technology?

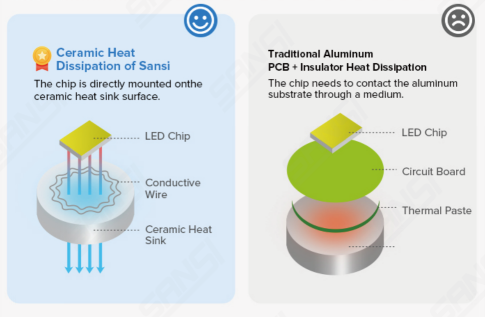

In contrast to MCPCB, ceramic substrate heat dissipation technology has emerged as a superior solution for high-power LED products. Ceramic heat dissipation technology directly attaches the LED chip to the ceramic, allowing heat to dissipate through air convection, providing better thermal performance than traditional MCPCB LED fixtures.

Advantages of Ceramic Heat Dissipation Technology

Ceramic substrates offer significantly higher thermal conductivity, often reaching 10 W/mK or more, allowing them to more effectively dissipate heat from LED chips. This helps to maintain LED brightness and performance stability. Unlike polymer insulation, ceramic materials are not only better at conducting heat, but they also exhibit excellent thermal stability and can withstand temperatures exceeding 200°C, making them ideal for high-power applications.

In addition, ceramic substrates have excellent electrical insulation properties, providing a more stable environment for circuit operation and reducing the risk of electrical failure caused by poor heat dissipation. The thermal expansion coefficient of ceramic materials is also better matched to the materials used in LED chips, reducing the thermal stress during packaging and extending the lifespan of LED products.

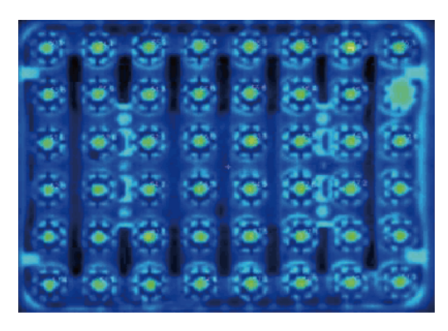

Compared to other products in the industry, Sansi’s independent ceramic heat dissipation technology also treats each light emitter as an independent pixel, effectively reducing heat accumulation, accelerating the heat dissipation process, lowering the junction temperature, and improving the light’s efficiency, lifespan, and reliability.

Versatility of Ceramic Substrates

Ceramic substrates not only excel in heat dissipation and insulation, but they also offer a range of additional benefits for industrial applications. First, ceramic materials are highly durable and resistant to corrosion, allowing them to perform reliably in harsh industrial environments. They can withstand exposure to strong acids, bases, and other corrosive chemicals, ensuring long-term reliability. Additionally, ceramic materials have a low dielectric constant, which improves signal transmission speed and reduces circuit latency.

The Future of Thermal Management

While MCPCB offers a cost-effective thermal management solution for low- to medium-power LEDs, its thermal performance and stability are insufficient for high-power applications. Ceramic substrates, with their superior thermal conductivity, insulation, and heat resistance, provide a more reliable and efficient solution for high-power LED products. As ceramic material technology continues to evolve, ceramic heat dissipation is poised to become a dominant thermal management solution in the future of industrial lighting.

Enhance Your Space with C2300-BE to Experience Brilliant Thermal Management

The Sansi C2300-BE LED industrial light is the perfect solution for energy-efficient, long-lasting illumination. Featuring Sansi’s unique ceramic pixel cooling technology, this light offers superior performance and durability, making it ideal for a wide range of industrial settings. It provides bright, clear lighting that enhances safety while reducing energy costs by up to 80% compared to traditional high bay fixtures. With a lifespan of 50,000 to over 150,000 hours, it requires minimal maintenance. Plus, with an IP65 protection rating and adjustable brightness, it’s designed to handle tough environments while keeping your space well-lit and secure, day and night.

Additionally, all of Sansi’s LED street lights, tunnel lights, security lights, floodlights, and high bay lights are developed using a unified ceramic pixel platform. There’s no doubt that our products can be an asset to your workplace construction and business operations. If you would like to learn more about our ceramic heat dissipation technology or need help selecting the right lighting solution for your space, feel free to reach out. We are here and ready to assist you.

As technology advances, people’s expectations for LED products continue to rise across various dimensions. Undoubtedly, ceramic cooling technology is poised to become a key solution to the heat management challenges of LED lighting, paving the way for higher-quality products. We are on the verge of witnessing this exciting innovation unfold.