In industrial settings, lighting is more than just a matter of visibility. It plays a critical role in safety, productivity, and energy efficiency. Selecting the right industrial lighting requires an understanding of specific parameters that influence performance and practicality. This blog will help you learn the meaning and effect of the parameters.

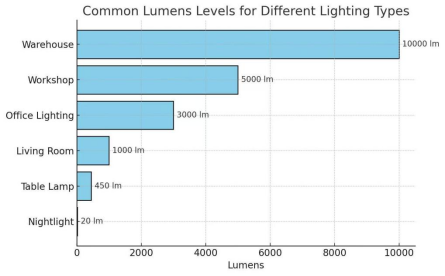

Brightness (Measured in Lumens)

Brightness is a key factor in industrial lighting, ensuring sufficient visibility in large spaces. Brightness is measured in lumens, not watts. While watts indicate power consumption, lumens measure the actual light output, which is also called luminous flux. It specifically refers to visible light, making it a more relevant measure for understanding how bright a light source will appear to the human eye.

Industrial areas like warehouses or production lines typically require high-lumen lighting solutions to illuminate vast areas without dark spots.

Relationship Between Luminous Flux and Other Lighting Parameters

Illuminance: Illuminance is the measure of luminous flux received per unit area, typically expressed in lux (lx). It describes the intensity of light on a surface, representing the brightness of the illuminated area.Different settings and activities require varying levels of illuminance. For example:

• Offices and Classrooms: 300-500 lx

• Production Workshops and Laboratories: 500-1000 lx

• Warehouses and Storage Areas: 50-200 lx

• Supermarkets and Retail Stores: 500-1000 lx

Luminous Efficacy: This is the ratio of luminous flux to power consumption, indicating the efficiency of a light source. Higher efficacy means more light is produced per watt of power consumed.

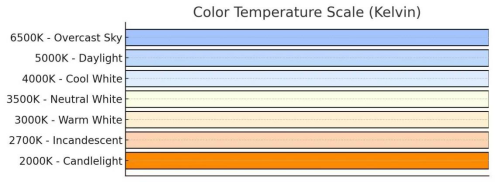

Color Temperature (Measured in Kelvin)

Color temperature is a measure of the color appearance of light emitted by a source, which affects the visual ambiance and productivity levels. It’s measured in Kelvin (K) and ranges from warm (lower Kelvin) to cool (higher Kelvin). Warm light (2000K-3000K) has a yellow or orange tone, creating a cozy, comfortable ambiance. Neutral light (3000K-4500K) has a more neutral white tone, providing a bright feel without being too harsh. Cool light (4500K-6500K) appears bluish-white, similar to daylight, and promotes focus and alertness.

Color temperature not only affects the lighting appearance but also has psychological and physiological effects on people. Studies show that cool light enhances alertness and focus. In industrial settings, a higher color temperature (4000K–6500K) is generally preferred, as it mimics daylight and enhances focus.

• Recommended Ranges:

• 4000K–5000K: Suitable for workshops and warehouses.

• 5000K–6500K: Ideal for task-heavy areas, providing a crisp, bright light that improves visibility.

Color Rendering Index (CRI)

The Color Rendering Index (CRI) is a measure of how accurately a light source reveals colors compared to natural sunligh. CRI ranges from 0 to 100, with higher values indicating better color rendering. A high CRI light source allows colors to appear more vibrant and true-to-life, making it ideal for settings where color accuracy is critical. For industrial environments where color differentiation is essential (such as in quality control or detailed work), a CRI of 80 or above is recommended.

Tip: For general industrial lighting, a CRI of 70–80 is often sufficient. For specialized tasks, consider lighting with a CRI above 90.

Energy Efficiency

Industrial facilities often have long operating hours, making energy efficiency a top priority. LED lighting is highly recommended for its lower energy consumption and extended lifespan compared to traditional options like fluorescent or halogen lights.

• Benefit: LEDs can save up to 50–70% in energy costs while reducing maintenance frequency.

• Consideration: Look for lighting fixtures with a high lumens-per-watt ratio, which indicates efficient light output relative to power consumption.

Lifespan and Durability

Industrial lighting must withstand harsh conditions, including high ceilings, dust, vibration, and sometimes extreme temperatures. LED lights typically offer longer lifespans, often exceeding 50,000 hours, and are more durable than other options.

• Tip: Check for IP (Ingress Protection) ratings. An IP rating typically consists of the letters “IP” followed by two digits. The first digit indicates the level of protection against solids, while the second digit denotes protection against liquids. Choosing an appropriate IP rating depends on the environment in which the equipment will be used. For example, IP65-rated lights are protected against dust and water, making them suitable for demanding environments.

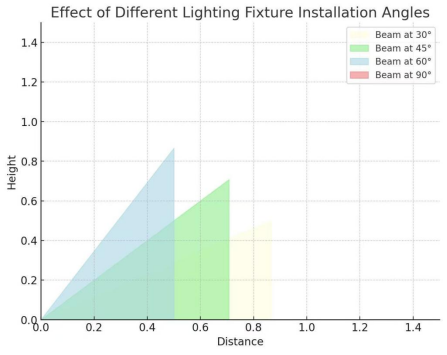

Beam Angle

The beam angle determines how light is distributed in an area. A narrow beam angle (e.g., 30–60 degrees) focuses light on specific areas, making it ideal for task lighting, while a wider beam angle (e.g., 90–120 degrees) covers larger spaces uniformly.

• Choosing the Right Beam Angle:

• Narrow Beam: For focused areas like workstations or inspection zones.

• Wide Beam: For general lighting in large open spaces.

Compliance and Safety Standards

Finally, ensure that your lighting meets industry-specific standards and regulations, such as OSHA guidelines for workplace lighting. Proper lighting reduces the risk of accidents and improves overall safety.

Making Informed Choices

Choosing the right industrial lighting involves a balance of brightness, color temperature, efficiency, and durability to suit the unique needs of industrial environments. By understanding these essential parameters, you can make informed choices that enhance productivity, reduce energy costs, and create a safer workspace. Whether you’re upgrading an existing facility or planning a new one, keep these factors in mind to optimize your industrial lighting setup.