Sansi LED: Sustainable LED Lighting and Integrated LED Display

Delivering premium and professional LED Display, LED Lighting, Smart City Integration solutions, trusted by over 60,000 companies worldwide everyday. From industrial lighting to commercial lighting, from outdoor advertising to XR & VR production, Sansi LED greatly improves the quality and sustainability of your business with 30 years of expert experiences.

LED street lights, as a new energy-saving lighting source, have been highly sought after by city builders since they came out. However, LED street lights still have many problems in practical applications. This article aims to analyze how temperature affects the lifespan of LED street lights specifically.

Theoretically, the total incident photon-to-electron conversion efficiency(IPCE) of LED is about 54%, the remaining electrical energy is released in the form of thermal energy. However, the actual photon-to-electron conversion efficiency is less than half of the theoretical value based on the current technical level. For LED street lights, when heat accumulates to a certain extent, the excessively high temperature will have a direct impact on the performance of LED street lights. When the temperature rises, the luminous efficiency of the LED chip will decrease. The correlated color temperature of white light will rise while color temperature of other colors will decrease, which results in visual deviation. Moreover, the epoxy resin material of the LED package is prone to cracks and moisture under a continuous high temperature environment.

Most LED street lights manufacturers on the market still use aluminum or copper as the heat sink material. The structure of this traditional heat dissipation module includes metal layer, polymer insulating layer and metal heat sink. This kind of thermal design places a high demand on the heat dissipation performance of the insulating layer, however polymer insulating materials have low thermal conductivity, which contributes to a bad heat conduction effect. It’s unrealistic to improve the thermal conductivity of the aluminum board directly because circuit can’t be attached to it without insulating layer.

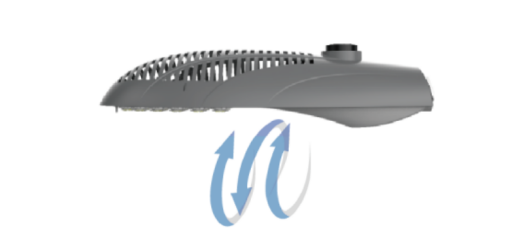

Based on the heat dissipation problem, SANSI firstly applied ceramics to the heat dissipation system of the road lights. The traditional McPCB (Metal Core PCB) is replaced by ceramics which has better thermal conductivity. The LED chips are directly attached to the heat sink. In this way, there is no longer need to use conventional heat transfer medium between the LED chips and the heat sink, which greatly reduces the system heat accumulation and lowers the junction temperature of the chips. This new technology brings lower light attenuation and longer lifespan to the road lights, ensuring its continuous and stable work.

With the continuous advancement of science and technology, the traditional inefficient heat dissipation system will inevitably be replaced. How to improve the heat dissipation performance has also become a major problem faced by many street lamp manufacturers.

-

NO DATA