As a display system provider, Shanghai Sansi attended the review meeting of a special project. At the meeting, LED display experts and suppliers of various systems had a discussion on the problems that may be encountered in the implementation of the project. As an important part of the project, the LED display system has been the discussion focus that received special attention from the participating experts. The project is close to the sea, with humid climate and high level of salty moisture. In order to ensure that the display product is not affected by moisture and salty moisture during its application, the weather resistance of the LED display product has to meet higher requirements.

For display systems in extreme environments, Sansi has a lot of project experience. Moreover, in the initial stage of research and development of each Sansi project, the display products have undergone operation tests in harsh environments to ensure that the products can maintain good operating conditions during their actual use.

For projects in coastal areas, products can be checked from the following aspects.

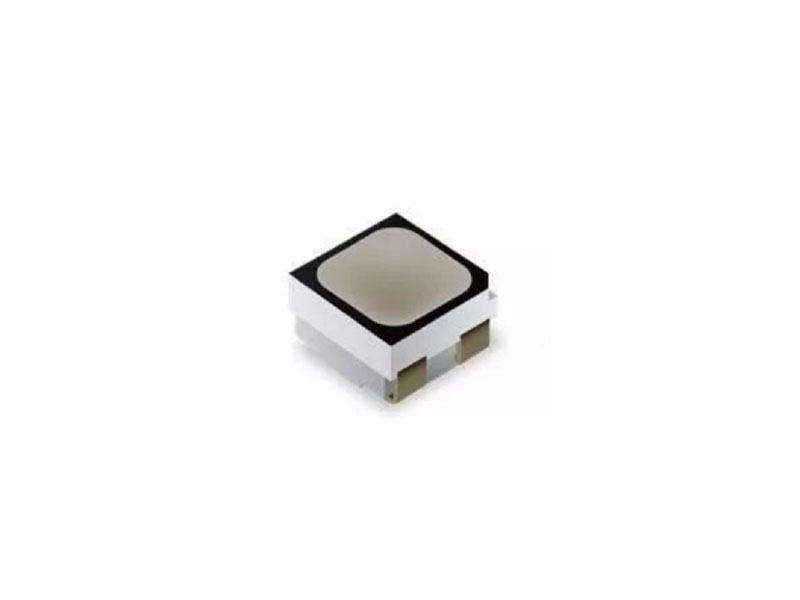

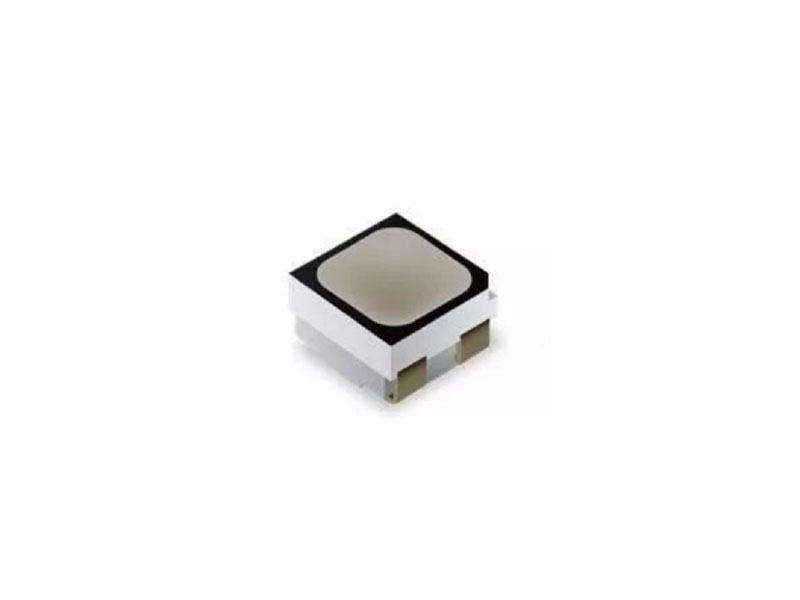

1. The choice of LED lamp beads: In the humid environment in coastal areas, small LED tubes are prone to electrode migration, resulting in the so-called "caterpillar" phenomenon. In such project, we will try our best to choose a light tube with a larger luminous tube volume while ensuring the dot pitch to reduce the "caterpillar phenomenon."

As shown in the figure above; the red, green, and blue LED light-emitting chips are packaged in the closed structure shown in the figure above. When the volume of the light-emitting chip remains unchanged; the closed structure that is the volume of the light-emitting tube, the larger the distance between the light-emitting chips, the smaller the possibility of electrode migration. Thereby effectively reducing the "caterpillar" phenomenon.

2. Protection of the components: For exposed components, in order to reduce the direct contact with moisture and salty moisture in the air, that the surface of the components on the back of the box can be painted with three-proof paint as to extend the service life of the components as long as possible.

3. Protection of LED lamp beads: LED lamp beads are an important part of the LED display. In order to ensure the service life of the lamp beads in a high salty moisture and high humidity environment, the surface of the LED lamp beads is coated with nano protective coating. This paint is a colorless, transparent material that forms a nano-protective layer on the surface of electronic components to completely cover the pins of electronic components, effectively preventing electronic components from wading in water and being corroded by acid and alkali salty moisture. Under the premise of not affecting the LED display effect, the erosion of the LED lamp beads by the external environment is reduced, and also the service life of the LED lamp beads is increased.